DIY Sump Pump Installation: Stop Basement Flooding for Good

Worried about water soaking your basement floor and ruining your things? Installing a sump pump yourself fixes that problem.

This guide walks you through the whole job. We will cover choosing the right pump and basin, digging and setting the pit, running the discharge line and electrical, and testing for leaks.

I’ve installed and serviced hundreds of these units. Do it right the first time with this straightforward method.

The DIY Sump Pump Installation: A Straight-Talk Verdict

Let’s cut to the chase. Installing a sump pump from scratch is a serious project. It’s not swapping a faucet. Replacing a well sump pump brings its own set of challenges. We’ll cover that in the next steps. I give it a solid 7 out of 10 on the difficulty scale.

You need three skill sets to tackle this job: the strength for concrete demolition, the precision for waterproof plumbing, and the respect for safe electrical work. Missing any one of these makes the project a poor fit for you.

What You Can Realistically Do Yourself

If you’re handy, you can handle the heavy lifting and assembly. This includes:

- Locating the best spot (the lowest point where water pools).

- Breaking and removing the concrete floor (it’s brutal work).

- Digging the hole for the sump basin.

- Placing the basin, surrounding it with gravel, and backfilling.

- Dry-fitting and cementing all the PVC discharge pipe inside your home.

- Mounting the pump and attaching the check valve.

Where You Must Call a Licensed Professional

Do not wing these parts. The risks and legal codes are clear.

- Electrical Connection: You must have a dedicated GFCI outlet installed by a licensed electrician. Running waterproof wire from the pump to a new circuit is not DIY.

- Drilling Through the Foundation Wall: Drilling the hole for the discharge pipe to exit your home requires a hammer drill and specific knowledge to avoid structural or rebar damage. Many pros do this.

- Final exterior discharge: Connecting the pipe outside and ensuring it drains properly away from your foundation often involves more digging and grading.

In most areas, code requires a licensed professional for the electrical work and sometimes for the foundation penetration. Skipping this can void your homeowner’s insurance if something goes wrong.

What This All Costs

Your wallet needs to know what it’s in for.

- DIY (Your Labor + Pro for Electrical/Penetration): $500 – $1,200. This covers a quality pump, basin, piping, gravel, tool rental, and paying an electrician and maybe a mason for their specific tasks.

- Full Professional Installation: $2,500 – $4,500+. This is the typical range for a complete, warrantied job where they handle everything from start to finish.

The DIY path saves money but demands your time, sweat, and project management. The pro path costs more but is a single call for a turn-key solution.

Tools and Materials Checklist: What You Need Before You Dig

Do not start until every item on this list is in your basement. A trip to the store mid-job with a hole in your floor is a nightmare.

Tools

- Sledgehammer

- Electric Demolition Jackhammer (rent this)

- Concrete Saw or Angle Grinder with masonry blade (for clean cuts)

- Shovel (a narrow trenching shovel works best)

- Bucket and Wheelbarrow (for concrete and dirt debris)

- 4-foot Level

- Tape Measure

- PVC Pipe Cutter or Hacksaw

- PVC Primer & Cement

- Utility Knife

- Pipe Wrench or Channel-Lock Pliers

- Wire Strippers/Cutters (for preparing the pump cord if needed)

- Drill/Driver

- Masonry Drill Bit (for anchoring the discharge pipe if required)

- Safety Gear: Gloves, Safety Gloggles, Hearing Protection, Dust Mask

Materials

- Pre-formed Sump Basin (typically 18-24 inch diameter)

- 1.5 to 2 cubic feet of Clean, Coarse Gravel (¾ inch crushed stone)

- Submersible Sump Pump (get one with a vertical float switch)

- PVC Discharge Pipe (Schedule 40, 1.5-inch is standard)

- PVC Fittings: Elbows (90-degree), Couplings, Male Adapters

- Check Valve (must be for sump pump use, with union for easy removal)

- Pipe Hangers or Straps

- Waterproof Silicone Caulk

- Hydraulic Cement (for patching the floor around the basin)

- Concrete Mix (for final floor patch)

- GFCI Outlet: This will be supplied and installed by your electrician.

- Waterproof Electrical Wire: Your electrician will specify and provide this (typically a dedicated circuit with UF-B wire).

A note on pipe size: you can reduce a sump pump line if you must. If your existing discharge line is 1.25-inch, you can use a reducing coupling to adapt your new 1.5-inch pipe to it. Use a full-size, gradual reducer, not a bushing, to avoid restricting flow. But for a new install, stick with 1.5-inch PVC pipe the whole way if you can.

First Steps: Planning and Locating Your Sump Pit

The first step isn’t buying a pump. It’s finding exactly where that pump needs to sit. Get this wrong, and you’ll be fighting water instead of managing it.

You need to find the lowest point in your basement floor where water naturally pools. This is your bullseye. Use a 4-foot level or, better yet, a laser level to map the floor’s slope and identify the absolute lowest spot. In my own basement, a corner that always felt damp was actually over an inch lower than the drain, making it the perfect target.

Once you’ve found the low spot, you need to choose the final pit location. Keep it away from heavy foot traffic areas and doorways. You don’t want someone tripping over the lid. Also, stay at least a foot away from any load-bearing walls or foundation footings. Digging too close can undermine their support.

Before you even think about swinging a sledgehammer, you must check for underground utilities. Call 811 or your local “Call Before You Dig” service a few business days before you plan to start. They will mark any gas, water, electrical, or communication lines. It’s free, it’s the law, and it prevents a very bad day.

Your local building department has rules for this. You must call them or check their website. Codes dictate how deep and wide your pit needs to be, often around 18 to 24 inches deep and 16 to 18 inches wide. They also strictly govern where your discharge line can go, usually requiring it to extend far enough from your foundation to prevent water from just cycling back. Ignoring code can get you fined and will definitely cause problems when you sell your house.

Water Science Snippet: It’s Not Just “Water”

The water seeping into your basement isn’t clean. Groundwater picks up Total Dissolved Solids (TDS) like iron, manganese, sand, and clay. My well water, for example, is heavy with iron, which stains everything orange.

This mineral and sediment cocktail is abrasive and accelerates wear inside the pump. That’s why you need a pump built with durable components, like a cast iron or stainless steel volute, not just plastic. Always choose a pump with a good intake filter screen to keep the bigger grit out, and expect to clean that screen annually.

The Gritty Work: Digging the Pit and Setting the Basin

How do you dig and prepare the sump pit?

This is the hardest part of the job. You are making a permanent hole in your basement floor. Pick your spot carefully, typically in a low corner where water already pools. Mark a circle about 12 inches wider than your basin’s diameter.

If you have a concrete floor, you need to cut it. Rent a concrete saw with a diamond blade. Wear a respirator, goggles, and hearing protection. The dust is brutal, so seal off the rest of the basement with plastic sheeting. Cut along your marked circle. I used a saw from my local tool rental, and it took about an hour for an 18-inch diameter cut.

Once the circle is cut, use a sledgehammer to break the concrete slab within the cut lines. Remove the broken chunks. Now you dig in the dirt. Use a spade and a trenching shovel. You need to go deep enough so the basin rim sits about 2 inches above the finished floor level.

Keep a shop-vac right next to the hole as you dig. Water will seep in. Vacuum it out continuously to keep the pit dry and see what you’re doing. This is the single best trick for keeping your sanity during this phase.

Dig down another 6 inches deeper than your basin height. This creates room for a gravel base. Tamp the soil at the bottom flat and firm.

How is the sump liner or basin installed and secured?

First, you need to prepare the basin. Most plastic sump liners come smooth. You must add inlet holes for water to enter. Using a hole saw drill bit, cut several 1/2-inch to 3/4-inch holes around the bottom third of the basin. Space them every 6 to 8 inches. These weep holes let groundwater seep into the basin from the sides and bottom. Next, you’ll dig and prepare the sump pit to receive the basin. Proper pit preparation ensures the unit sits level and drains correctly.

Pour 4 to 6 inches of washed gravel (3/4-inch stone works well) into the bottom of your dug pit. This is your drainage bed. Place the basin on top of the gravel. Now, the critical part: leveling.

Get a long level and place it across the top rim of the basin. Check it from multiple angles. A basin that isn’t level can cause the pump to lean, wear out prematurely, or trigger the float switch incorrectly. Add or remove gravel underneath the basin until it is perfectly level in all directions.

Once level, pour more washed gravel into the gap between the outside of the basin and the dirt walls of your pit. Fill this space all the way up to just below the basement floor level. The gravel provides stable support and channels water toward the weep holes.

At the very top, where the concrete floor meets the basin, you will later seal it with hydraulic cement. For now, the basin should be locked in place by the gravel and sitting level, ready for the pump.

Plumbing and Pump Setup: The Heart of the System

Connecting the Discharge Pipe

This pipe is what gets the water out of your basement and away from your foundation. Do it wrong, and you’re just recycling water back into the ground next to your house.

Here is how to connect the discharge pipe correctly.

- Drill the Exit Hole. You need to drill through the rim joist or foundation wall to get outside. Use a hole saw bit that’s at least 1/4 inch larger than your pipe’s outside diameter. This allows for a snug fit and room for the fitting.

- Install a Proper Sill Cock or Bulkhead Fitting. Do not just shove PVC through the hole. You must use a proper exterior rated fitting, like a frost free sill cock or a bulkhead fitting, to seal the hole and prevent pests, drafts, and more water from getting in. Caulk around it thoroughly on both the inside and outside.

- Create a Downward Slope. From the pump’s check valve all the way to the pipe’s end outside, the pipe must slope downward. Aim for at least a 1/4 inch of drop for every foot of pipe. This ensures water drains completely and doesn’t sit and freeze in the line.

- Direct Water Away. The pipe should terminate at least 10 feet away from your foundation. Use an elbow to point the opening toward the yard (not at your neighbor’s house). Adding a pop up emitter or splash block prevents erosion.

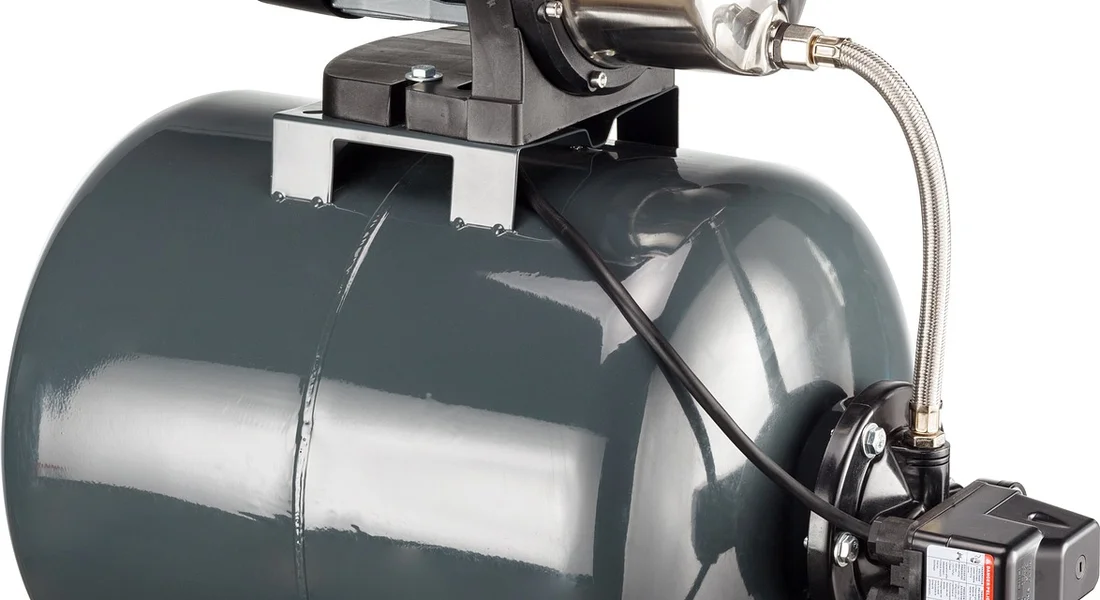

The check valve is a non negotiable part of this setup. It’s a one way street for water, installed on the vertical pipe just above the pump. Its job is to stop the thousands of gallons of water in the discharge pipe from flowing back into the pit every time the pump shuts off. Without it, your pump would cycle on and off constantly, wearing out in no time. A missing or failed check valve also causes a loud “thump” known as water hammer when the pump stops.

Installing the Pump in the Pit

Getting the pump positioned right inside the sump pit is what makes the system work automatically and reliably.

Follow these steps for a proper installation.

- Elevate the Pump. Never set the pump directly on the pit’s floor. Sediment will get sucked in and kill it. Set it on a couple of solid bricks, a small patio block, or a manufactured pump pedestal. This keeps the intake above the muck.

- Connect the Discharge Pipe. Connect your vertical PVC pipe to the pump’s discharge port using the correct threaded adapter. Use Teflon tape or pipe thread sealant on all threads. Make this connection tight and secure.

- Align the Float Switch. This is the brain of the operation. For a vertical float on a rod, set the start and stop levels. Typically, you want the pump to kick on when water is about 12 inches deep and shut off when it drops to around 4 inches. For a tethered float, ensure it can swing freely without getting caught on the pump or pit wall.

- Do a Manual Test. Plug the pump into a dedicated GFCI outlet. Before you backfill or finish anything, slowly pour at least 5 gallons of water into the pit. Watch the float rise. The pump should kick on and move the water. Let it run and shut off automatically. This verifies everything works.

Yes, you can manually start most sump pumps. If you need to test it or trigger it during a dry spell, simply lift the float switch by hand. On a vertical float, lift the float up its rod. On a tethered float, lift the floating ball. This manual override lets you verify the pump motor runs without needing a full pit of water. It’s a good practice to test your sump pump regularly to stay prepared. Regular checks can catch problems before storms. Just don’t run it dry for more than a few seconds.

Power, Wiring, and The Final Connection

This is where the job gets serious. Water and electricity don’t mix. Working in a wet pit is a genuine hazard. If you are not 100% confident working with household electrical circuits, hire a licensed electrician for this part of the installation. It’s not worth the risk.

How is the electrical wiring and check valve installed?

These are two separate but critical final steps. The check valve keeps water from draining back into the pit, and the electrical connection makes the pump work. Get both wrong, and your pump will fail when you need it most.

Installing the check valve is straightforward, but must be done correctly. It gets installed on the vertical discharge pipe, close to the pump. The arrow on the valve body must point away from the pump, toward the exterior. This allows water to push out but not flow back down. Use stainless steel hose clamps on both sides of the valve, not the plastic ones that come in the box. In my own basement, I use a clear check valve so I can actually see if water is trying to flow backwards-it’s a great visual check.

For the wiring, you need a dedicated outlet. The pump cord is short for a reason-it’s not meant to be plugged into an extension cord running across your basement. You must have a Ground Fault Circuit Interrupter (GFCI) outlet installed on a dedicated circuit for the pump. This protects you from a lethal shock if the pump or wiring gets wet. Electrical code for sump pumps typically requires a dedicated 15–20 amp circuit with GFCI protection and a local disconnect. All wiring on that circuit should be weatherproof and properly protected from moisture. The electrician will run conduit and wire from your electrical panel to a weatherproof outlet box mounted on a joist near the sump pit, but not directly above it where condensation can drip.

Mandate the use of a dedicated GFCI outlet and explain safe wire routing.

Let’s be clear: a standard outlet or using an extension cord is a code violation and a major safety hazard. A dedicated GFCI is not a suggestion; it’s a requirement in the National Electrical Code for basement sump pumps.

Safe wire routing means keeping everything up and out of the way. The pump’s power cord should be plugged directly into the GFCI outlet. Any excess cord should be neatly tied up to a joist with a zip tie, leaving a small service loop. Never let the cord dangle into the pit. The discharge pipe, check valve, and wiring should all be secured to basement joists or walls with pipe hangers and conduit straps. This keeps your basement tidy and prevents anything from getting knocked loose.

Touch on smart integrations: “do sump pumps have alarms?” and “can an alarm be added to an existing sump pump?” and even “can alexa turn on my sump pump?” for modern setups.

Modern pumps offer more than just pumping. Many come with a built-in tethered float switch that can trigger an audible alarm if the water rises too high, indicating a pump failure. If your pump doesn’t have one, you can absolutely add a battery-powered water alarm to the pit for about $20. It’s a cheap insurance policy that screams when water gets too high.

For true smart home integration, you need a separate device. You can’t have Alexa directly “turn on” a standard sump pump. But you can install a smart water sensor in the pit that sends an alert to your phone. More advanced systems involve a whole-house water monitor that attaches to your main line and can detect leaks or sump pump failures. I use a simple WiFi sensor in my pit. If it gets wet, my phone lights up no matter where I am. It’s peace of mind.

Testing, Troubleshooting, and Long-Term Care

The First Test Run

Your pump is in the pit and wired up. Now you prove it works. This isn’t optional. You need to know it will activate before the next rainstorm.

Here is the exact process for testing your newly installed sump pump. Get a 5-gallon bucket of water. Plug the pump into its dedicated GFCI outlet. Slowly pour the water into the sump pit. Watch the float. As the water level rises, the float should lift. The pump should kick on before the water reaches the top of the pit. You will hear the motor and see water shooting out of the discharge pipe outside. The pump should run until the water level drops and the float falls, shutting it off. For ongoing reliability, consult our sump pump inspection maintenance guide for regular checks and maintenance tasks. It covers seasonal inspections and alarm tests to keep your system in top shape.

Can you test a sump pump dry? Absolutely not. Never run a submersible sump pump without water, as the water is what cools and lubricates the pump’s motor. Running it dry for even a short time can overheat and burn out the motor seals. Always pour in water to test.

Once testing is complete, do the final site work. Backfill around the liner with the gravel you excavated. Tamp it down firmly. This stabilizes the liner and promotes good drainage. Clean up all debris from the work area. A clean basement floor helps you spot new water leaks immediately.

The “Red Flag” Troubleshooting Guide

Your sump pump will talk to you. Learn its language. These sounds and behaviors mean you have a problem that needs your attention right now.

- The pump runs constantly or cycles on and off every few minutes. This usually means a massive water inflow (like a burst pipe) or a stuck float switch. Check that the float can move freely without hitting the pit walls or discharge pipe.

- You hear strange noises: grinding, rattling, or loud humming. Grinding often means a worn impeller or debris caught in the pump. Rattling could be a loose discharge pipe. A loud hum without pumping usually signals a jammed impeller or a failing motor.

- The pump has no power. First, check the GFCI outlet. Press the “Reset” button. If it won’t reset, the circuit may be faulting. Check your home’s breaker panel. If power is confirmed, the pump’s internal wiring or motor may have failed.

- The GFCI outlet trips immediately when you plug the pump in. This is a serious sign of a short circuit or water intrusion in the pump’s electrical components. Unplug it. The pump likely needs replacement.

- Water is not discharging outside, or it’s backing up. The discharge line is frozen, clogged, or the check valve is installed backward. Inspect the exterior outlet. Clear any ice or debris from the pipe opening.

System Maintenance Roadmap

A sump pump is an appliance. It needs basic care to be reliable. Follow this simple schedule to avoid a wet basement emergency.

Test the pump every single month. Pour a bucket of water into the pit and watch the cycle. This is the most important thing you can do.

Every six months, clean the sump pit. Unplug the pump. Scoop out any silt, gravel, or debris. This prevents clogs. Visually inspect the check valve on the discharge pipe for cracks or mineral buildup. Thoroughly cleaning the sump pit itself completes this routine. The next steps will include a detailed guide on maintaining a clean sump pump pit.

Inspect the discharge line exit seasonally. In fall, make sure leaves aren’t blocking it. In winter, ensure the opening isn’t frozen shut. In spring, clear away any mud or yard waste.

A typical sump pump lasts 5 to 10 years. If your pump is older, start budgeting for a replacement. Signs it’s time include: it runs much more frequently than before, it takes longer to pump out the same amount of water, or it requires constant switch adjustments or minor repairs.

What Helped Me: A Personal Story

I learned this lesson the hard way. In my first house, the discharge pipe had a steady drip back into the pit after every cycle. I ignored it. That constant trickle kept the float slightly raised, causing the pump to cycle on for just two seconds every ten minutes. It wore the motor out in three years.

The fix was a fifteen-dollar check valve and ten minutes of work. That tiny amount of backflow, called “short cycling,” is a silent pump killer. Now, the first thing I listen for after installation is a clean shutoff with no water falling back into the pit. If you hear that trickle, install or replace your check valve.

Common Questions

What’s the very first thing I should do before buying any parts?

Find the lowest spot in your basement where water pools; that’s your target. Then, call 811 to have underground utilities marked before you ever swing a hammer. Finally, check with your local building department for pit depth and discharge line codes.

What’s the one tool I shouldn’t try to skip renting?

An electric demolition jackhammer. Breaking through a concrete floor with just a sledgehammer is brutally inefficient. Renting the right tool saves your back and your weekend.

How do I make sure the discharge pipe won’t freeze or cause problems?

It must have a continuous downward slope (1/4″ per foot minimum) to drain completely. Terminate it at least 10 feet from your foundation, and use a proper frost-free sill cock or bulkhead fitting where it exits your house to seal the hole.

What’s the correct way to do the very first test?

Plug the pump into its dedicated GFCI outlet and slowly pour a 5-gallon bucket of water into the empty pit. Watch the float switch lift to automatically start the pump, and verify water is discharging outside. Never run the pump dry.

After everything is working, what’s my simple long-term care plan?

Test the pump monthly by pouring water into the pit. Every six months, unplug it, clean out debris, and inspect the check valve. Listen for changes in normal operation sounds-they are your first warning sign of trouble.

Final Steps to Seal the Deal

Pour water into the sump pit to test the pump the moment it’s installed. This live check confirms your work and stops basement flooding before it ever starts. A detailed install/test/troubleshoot guide follows in the next steps. It explains testing, diagnosing, and confirming reliable operation.

Bob McArthur

Bob is a an HVAC and plumbing industry veteran. He has professionally helped homeowners resolve issues around water softeners, heaters and all things related to water systems and plumbing around their homes. His trusted advice has helped countless of his clients save time, money and effort in home water systems maintenance and he now here to help you and give you first hand actionable advice. In his spare time, Bob also reviews home water systems such as tankless heaters, water softeners etc and helps home owners make the best choice for their dwelling. He lives around the Detroit area and occasionally consults on residential and commercial projects. Feel free to reach out to him via the contact us form.